Quality control software is an essential tool for companies looking to ensure their products or services comply with established quality standards and norms. It is a software application specifically designed to help businesses monitor, assess, and improve their production or service delivery processes.

This type of software offers a centralized platform where companies can manage all aspects of their quality system, from documenting processes to managing non-conformities, capacity planning, audit scheduling, APQP (Advanced Product Quality Planning), and generating reports.

Quality control software also includes advanced features such as product traceability, statistical data analysis, risk management, and integration with other enterprise systems like ERP (Enterprise Resource Planning) or PLM (Product Life Management).

Implementing effective quality control software requires careful planning and the execution of several critical steps. Here are the key steps to follow for a successful quality control software deployment:

APQP (Advanced Product Quality Planning): This feature enables advanced quality planning by aligning development stages with requirements and industry standards. It facilitates internal communication and collaboration throughout design and development phases, involving suppliers and ensuring a proactive approach to product and process quality management.

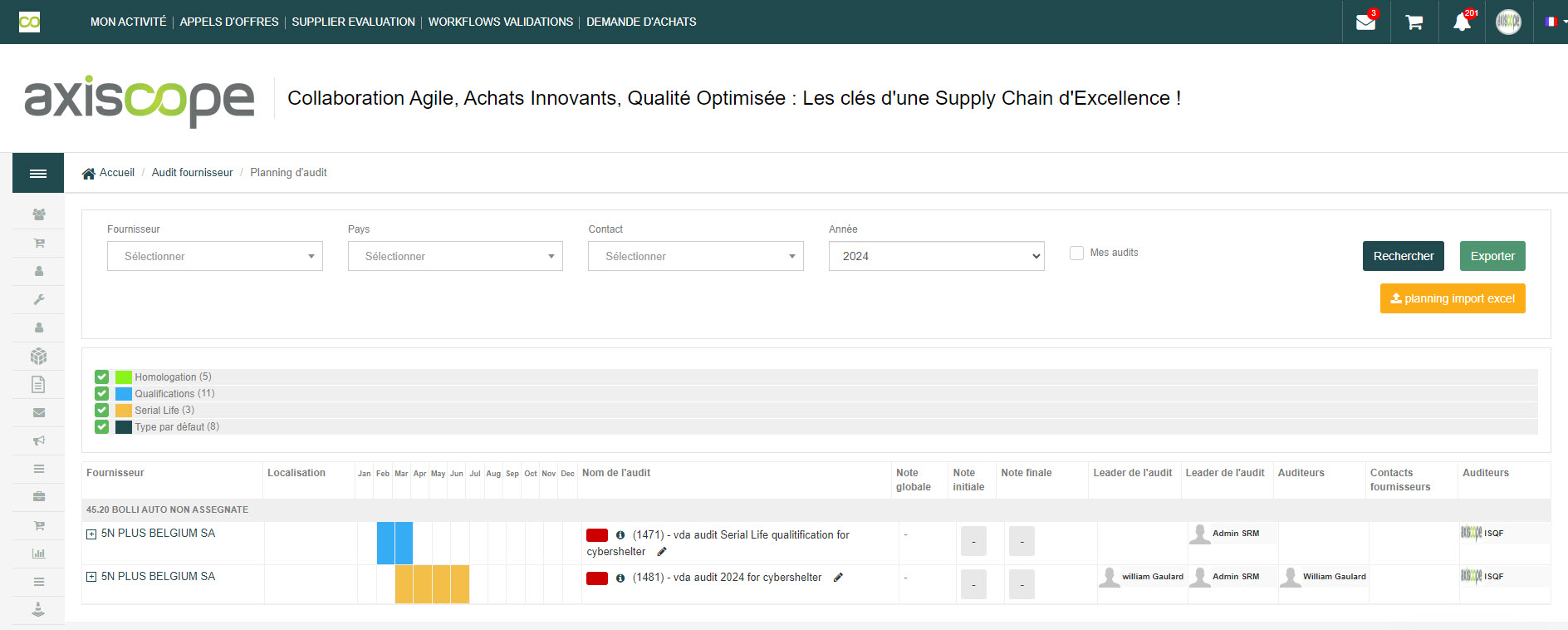

Audit: This tool provides resources for planning, executing, and tracking internal and external audits. It helps maintain supplier compliance with international standards and regulatory requirements, supporting continuous improvement by offering valuable insights on quality management system performance.

Non-Conformance: This feature enhances your company's ability to manage supplier non-conformance incidents by recording, classifying, and analyzing deviations from established standards. It also allows for implementing effective corrective and preventive actions with suppliers to avoid recurring issues.

Charge Back: This feature manages financial penalties related to quality deviations in products and services. It helps companies track costs associated with product returns, claims, and other quality incidents, ensuring better financial management and increased supplier accountability.

Capacity Management: Designed to evaluate and manage supplier production capacity in line with quality standards, this feature allows companies to anticipate resource needs, optimize existing capacities, and plan for future expansions based on quality and performance analysis.

Exemptions: This feature provides structured management of temporary exceptions to quality standards requested by suppliers. It enables users to document, evaluate, and approve these exemptions, while ensuring that compensatory measures are in place to maintain safety and compliance.

Staff training is crucial to the successful implementation of quality control software. Here are some tips for effective training:

Quality control software enables companies to better manage and adhere to the quality standards and norms of their industry. By centralizing process documentation, automating tracking and verification tasks, and facilitating the generation of reports compliant with ISO or other standards, these tools ensure optimal compliance with regulatory requirements.

A major advantage of quality control software is its ability to optimize internal processes. By identifying inefficiencies, bottlenecks, and sources of non-conformance, this software helps implement corrective and preventive measures to continually improve processes. This results in increased operational efficiency, reduced costs and production times, and better resource management.

Finally, quality control software contributes to increased customer satisfaction by ensuring consistent product or service quality. By guaranteeing compliance with customer-specific requirements, quickly identifying and correcting quality issues, and providing complete product traceability, these tools help build customer loyalty and enhance the company’s reputation in the market.

Our quality control software offers a complete range of features designed to meet the specific needs of businesses for quality management. Here is an overview of the main features our software provides:

Create, document, and track your company’s quality processes in a centralized manner.

Identify, document, and track non-conformances to take appropriate corrective actions.

Store and manage all quality documents in compliance with ISO and other applicable standards.

Analyze quality data to identify trends, discrepancies, and improvement opportunities, and generate detailed reports.

Track product traceability throughout its lifecycle, from design to delivery.

Identify, assess, and manage quality-related risks to minimize negative impacts on your business.

Integrate our quality control software with other enterprise systems, such as ERP and PLM, for effective quality management at all levels.

Before selecting quality control software, it’s essential to conduct an in-depth analysis of your company’s specific needs. What are your goals for using this software? What features are essential to meet your business requirements? By clearly identifying your needs and priorities, you can focus your search on solutions that best fit your business.

Once your needs are defined, evaluate the features offered by various quality control software on the market. Ensure that the software provides all essential features for your business, such as APQP and Capacity Management, non-conformance tracking, Charge Backs, exemption management, and report generation. Also, compare the advanced features each solution offers to see if they meet your specific requirements.

Lastly, consider the software’s integration with your existing systems and processes, as well as the level of customer support offered by the provider. Ensure that the software can be easily integrated with other business tools, like ERP or PLM, and check for responsive technical support if needed. Good customer support can make a significant difference in the adoption and successful use of the software in your business.

A major trend in quality control software is the growing integration of artificial intelligence (AI) and machine learning. These technologies allow quality control software to process and analyze large amounts of data faster and more efficiently than ever. With AI, software can automatically detect trends, identify anomalies, and predict future quality incidents, enabling companies to take preventive actions before issues arise.

Machine learning also enables quality control software to learn and adapt based on the data it analyzes, improving its accuracy and problem-detection capabilities. By incorporating these advanced technologies into quality control software, companies can enhance operational efficiency, reduce non-compliance risks, and ensure higher-quality products or services.

Another important trend in quality control software is the increasing focus on user experience (UX). Companies are recognizing the importance of designing user-friendly software that provides a smooth and enjoyable experience. By improving software ergonomics, usability, and intuitiveness, quality control solution providers can encourage wider adoption and more effective use of their products.

This trend translates into more intuitive user interface designs, simplified features, and streamlined processes. By focusing on user experience, companies can maximize the value of their investment in quality control software, ensuring successful user adoption and optimizing operational efficiency.

Leveraging the latest technological advances, Axiscope Digital Sourcing & Procurement Platform covers the full cycle of Procurement and Quality management to help buyers improve supplier reliability, streamline supplier relationships, drive procurement actions and commitments, digitize invoicing, and improve the quality of products and services.

Axiscope DSP integrates advanced Quality Assurance Process Management modules to coordinate the development of new products with suppliers, better manage compliance, and anticipate supplier-related risks. Through features like APQP (Advanced Product Quality Planning), non-conformance management, and capacity analysis, Axiscope DSP supports a proactive approach to quality management and supplier collaboration.

These modules also include standards-compliant audits, such as VDA or IATF, allowing continuous verification of supplier adherence to international norms and regulations. The system enables ongoing tracking of quality issues and corrective actions to ensure that products meet stringent quality and compliance standards.

With APQP modules, deviation request tracking, improvement plans, and non-quality cost management ("Charge Back"), Axiscope DSP extends Supplier Relationship Management (SRM) to include comprehensive Supply Management. This allows businesses to maintain effective risk control and foster innovation early in the procurement process, strengthening the entire supply chain.

Through Axiscope DSP, all company stakeholders can benefit from high-performance procurement, grounded in effective internal collaboration and supplier engagement. This fosters proactive supplier management, enabling companies to mitigate risks and encourage innovation early in the full procurement and supply management lifecycle.

Nous avons un réseau social dédié à la communauté NTIC. Si vous êtes inscrit ou souhaitez le rejoindre, cliquez sur le lien suivant www.axiscope.fr